Noah Wiley

njwiley@mit.edu

njwiley@mit.eduBoston, MA | San Francisco, CA

Electric UTV

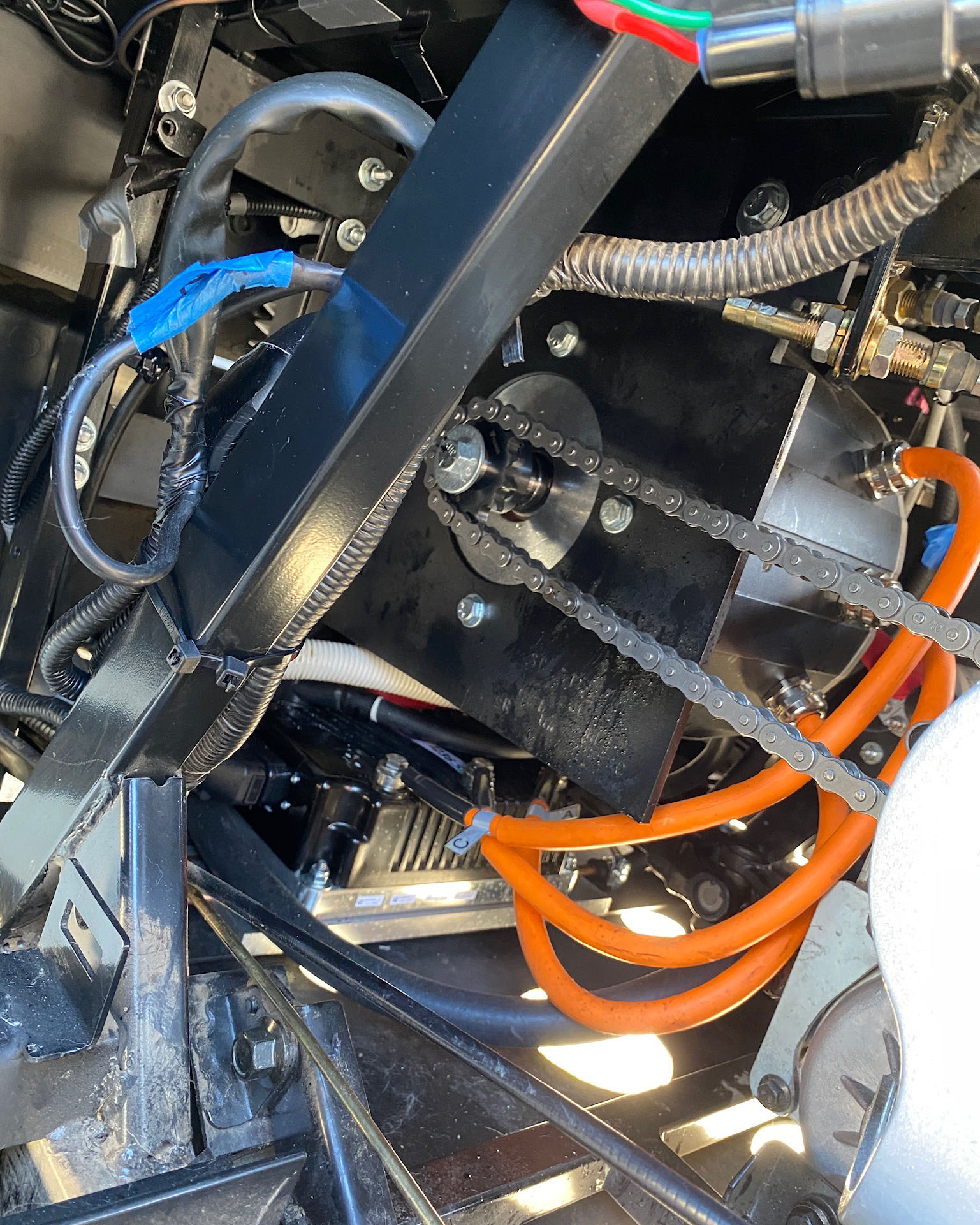

Successfully electric UTV conversion replacing a 22 horsepower gas system with a 96v 32KW (43HP) brushless watercooled motor, solar charging, fast charging, and custom controls. Worked with a team of dedicated schoolmates and local companies to design, manufacture, and trouble shoot mechanical, electrical, and control systems.

Details

- Role: Founder and Team Leader

- Dates: 2021 - 2022

- Vision: Combine the newest electric vehicle and battery technology to build a robust custom EV.

Goals

- In budget (5k or less)

- 50% better performance (acceleration and speed) than stock

- Street worthy, local roads does not have to be highway worthy

- Maintain 4wd, gauges

- Add Solar Panel Roof for Charging

- 30 mile range

Gallery

Design and Process

First Steps: Before any work could be done on the UTV, Noah advertised the project, identified a sponsor, and assembled a team of dedicated schoolmates. The team was split into subgroups to tackle the drive systems, electrical systems, and integration.

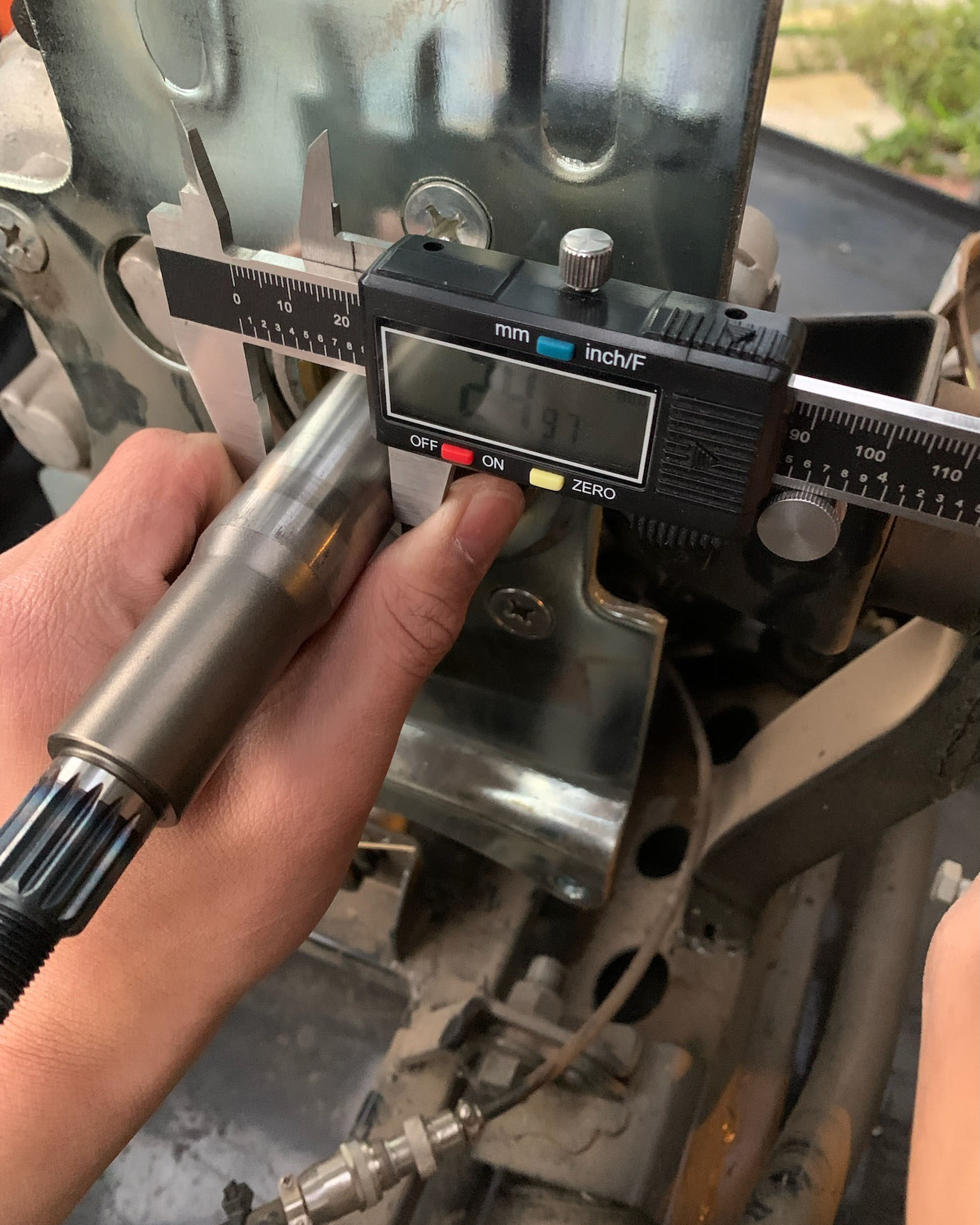

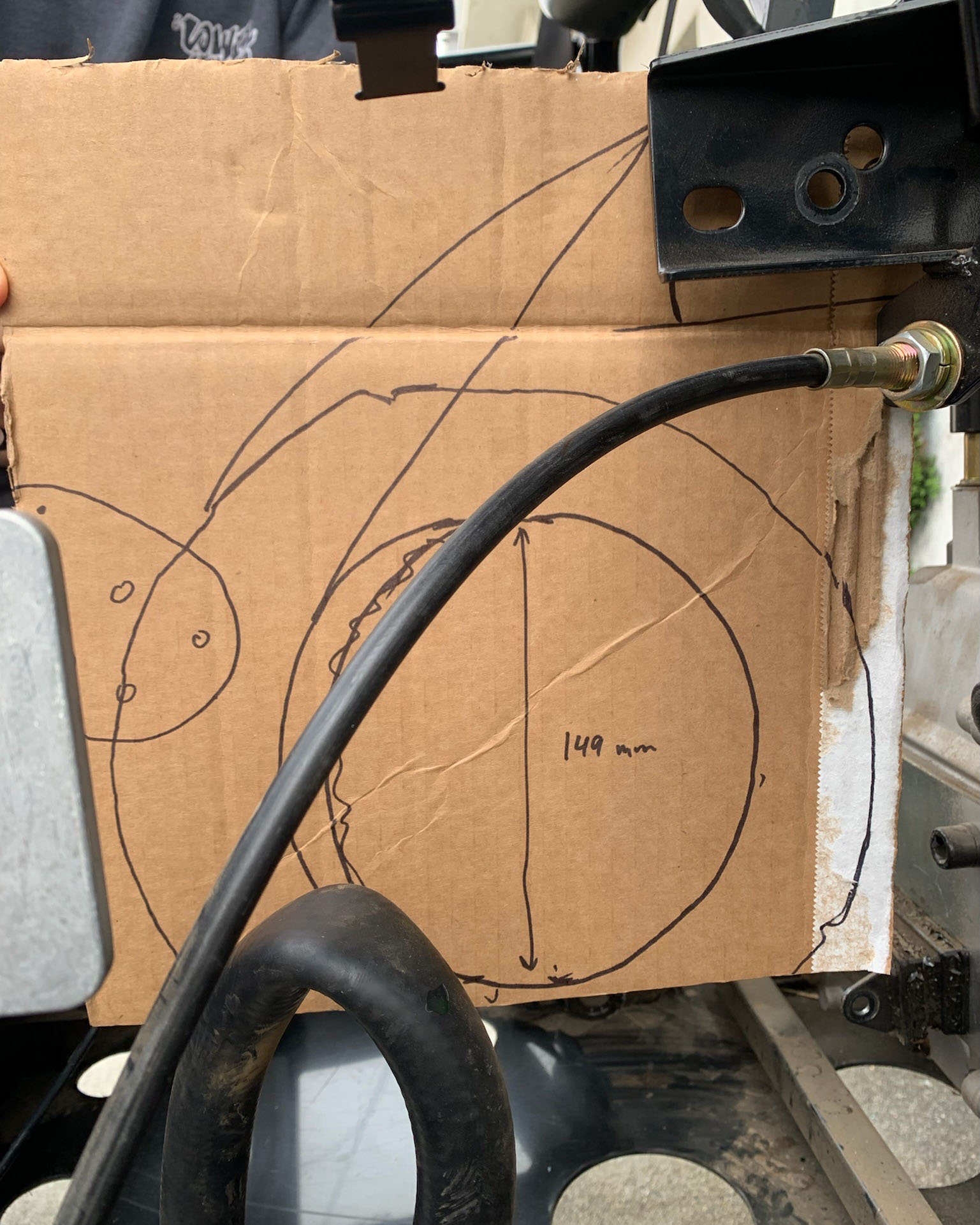

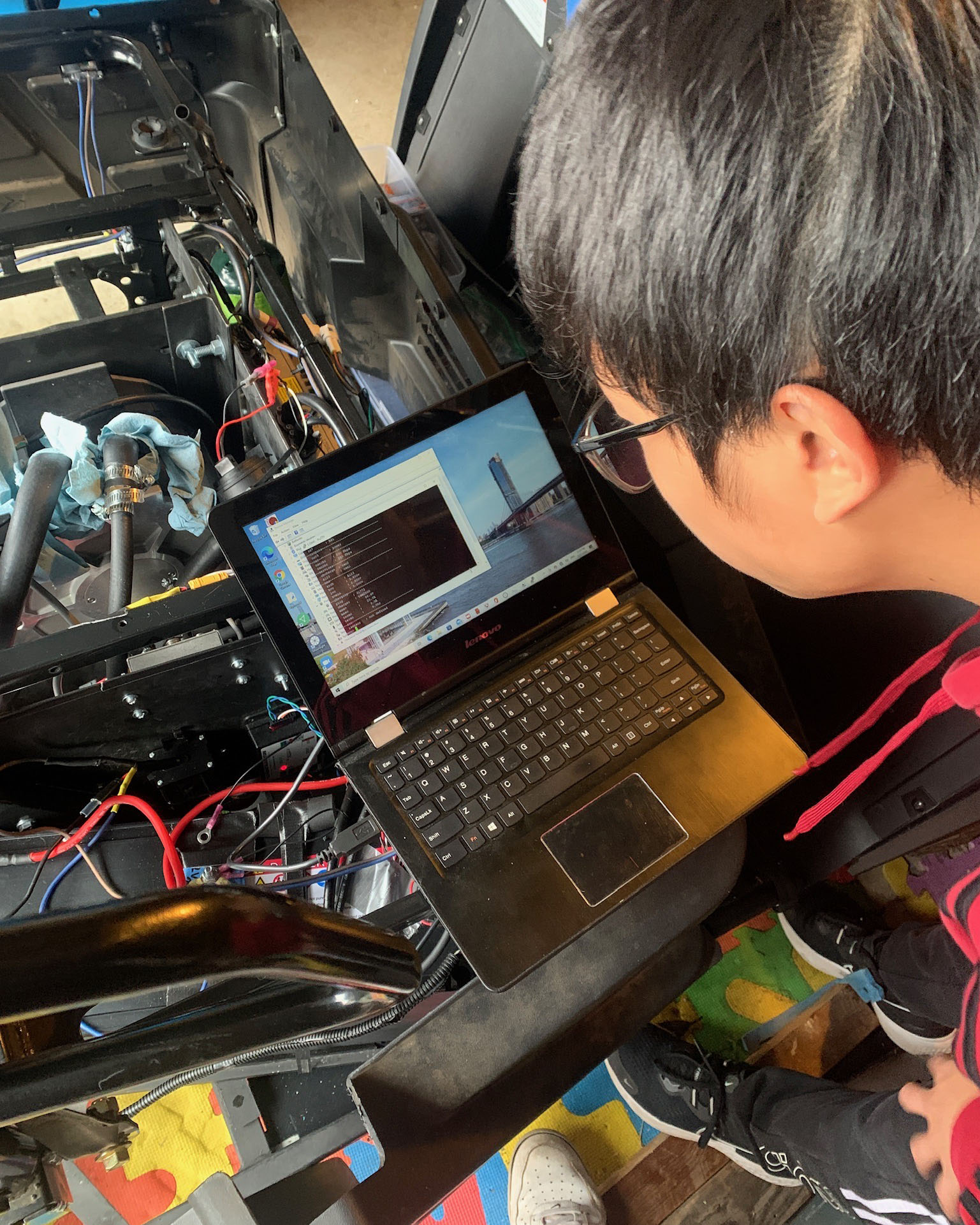

Design: Subteams coordinated to design custom motor attachments, battery mounts, and electrical systems before fabrication. The team aimed to utilize as many existing components like mounting points, wiring harnesses, and displays to stay in budget.

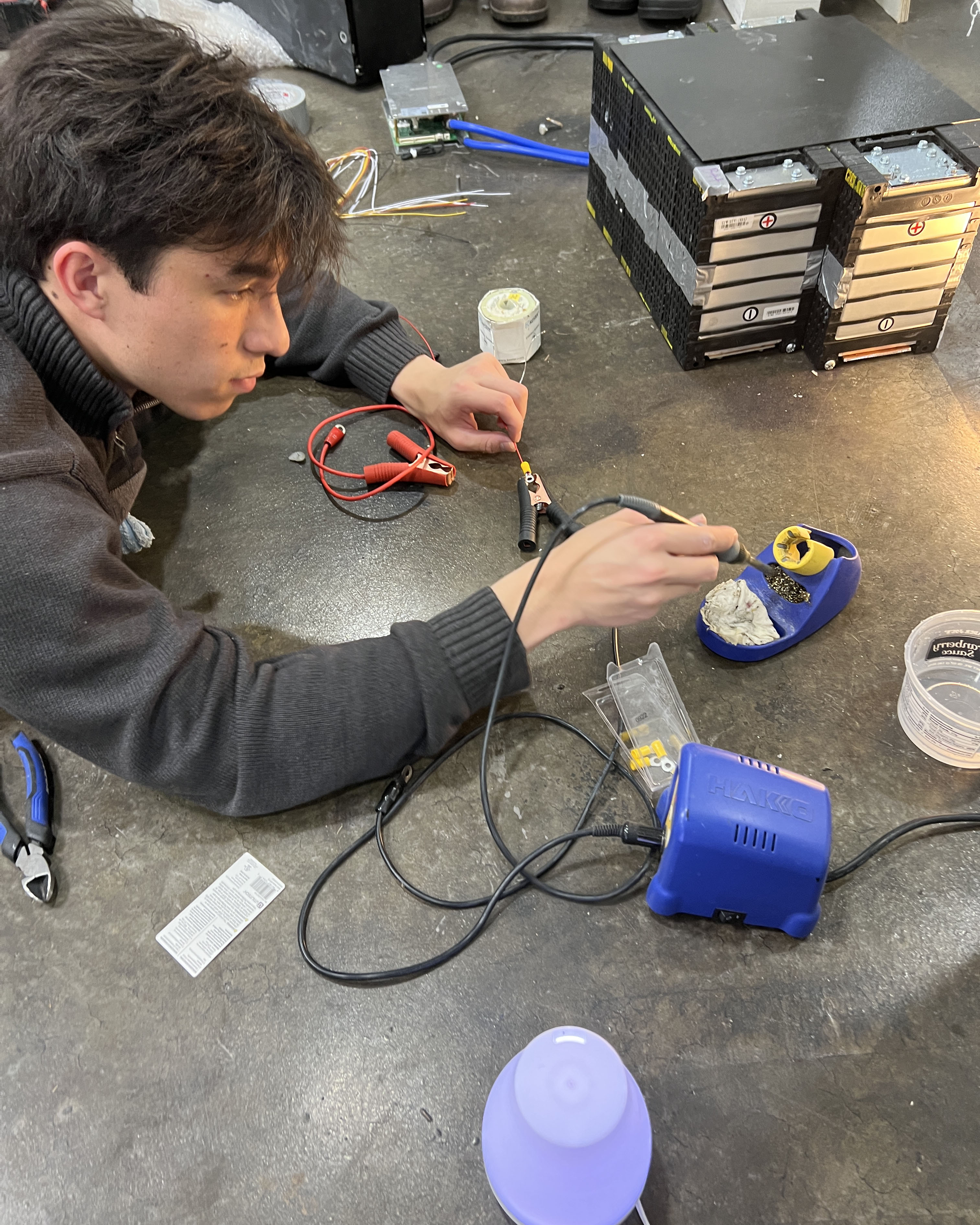

Fabrication: With the help of a local machine shop the team fabricated the motor mount out of a square foot of 3/8in steel plate, water cooling tubing, battery trays, and a direct drive pulley using the old flywheel.

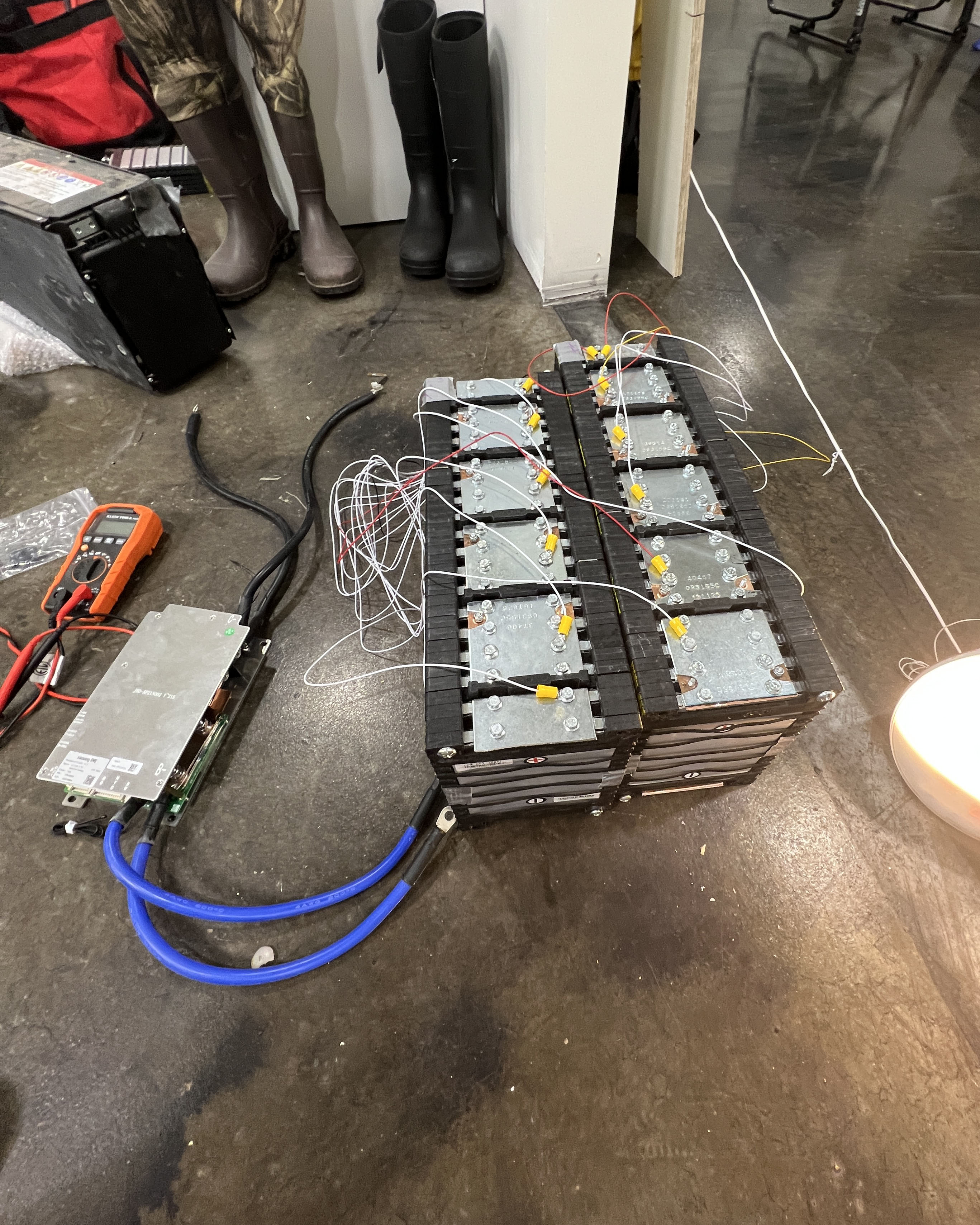

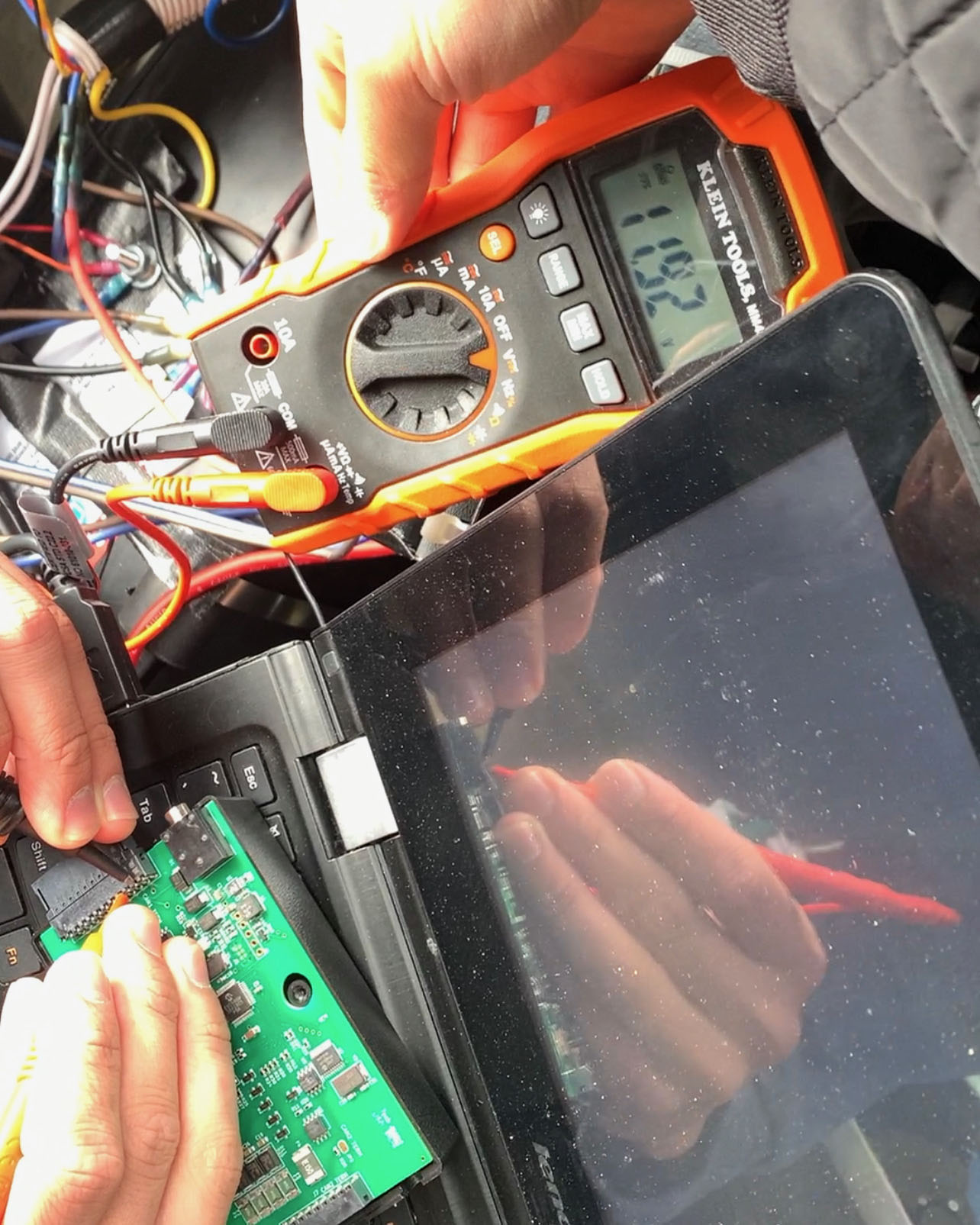

Integration: The 96v system was integrated alongside the 12v system, and the VCU was programmed to control the motor, battery management system, and battery gauge. The old display was configured to output odometry data and control 4wd. The team also added a solar panel roof to charge the batteries while driving or parked.

Challenges: After a surprisingly early first drive, we encountered problems with parasitic battery drain and a non-responsive VCU. Further isolation of our high and low voltage systems eliminated unwanted drain, and a careful circuit analysis of the VCU led us to an unexpected software bug. Two years later, the first unservicable battery pack went bad and was replaced with custom servicable pack with bluetooth cell tracking.